How Many Cfm Is A 5 Ton Unit

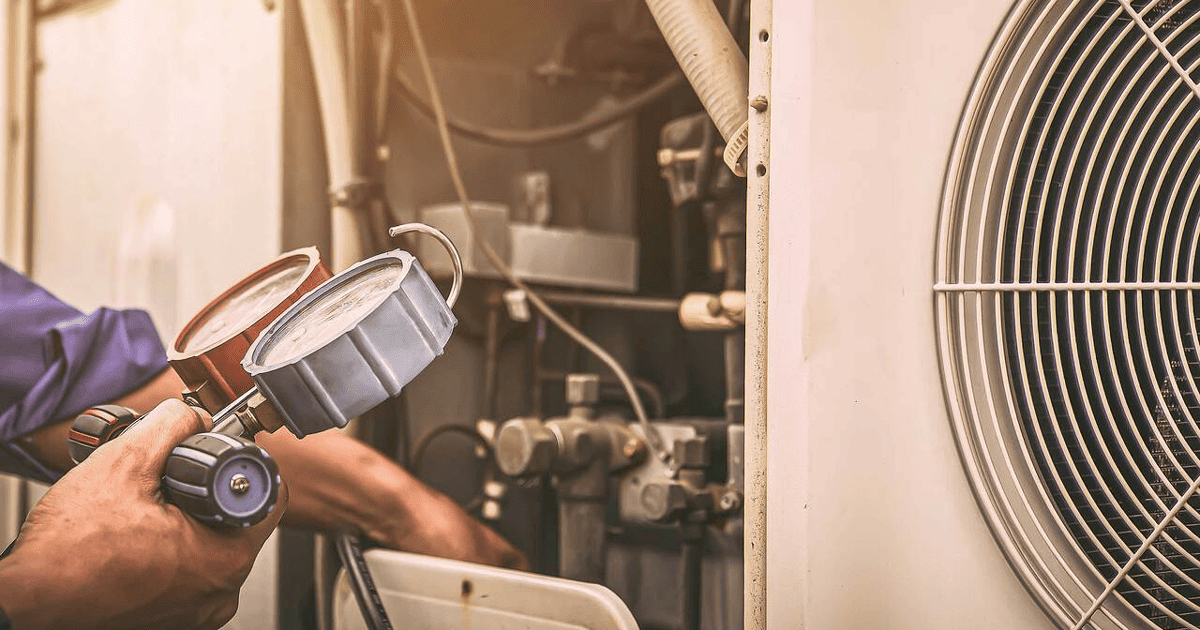

Did you know that the optimal airflow in an HVAC system can significantly impact its cooling efficiency? When it comes to a 5-ton unit, the question of how many CFM (cubic feet per minute) is required becomes crucial. According to industry standards, 400 CFM per ton of air across the evaporator coil is a general rule of thumb. That means a 5-ton unit would typically require 2,000 CFM.

However, this guideline may not always hold in every situation due to factors like relative humidity and insulation quality. For example, a higher CFM per ton might be necessary for effective cooling in hot and humid climates. Conversely, well-insulated homes may require less CFM.

To determine and optimize the ideal CFM for your 5-ton unit, various considerations, such as ductwork sizing and proper calculations using CFM calculators, are essential. This article will delve into these aspects and highlight common issues with CFM in HVAC systems to help you achieve optimal cooling performance. (Learn How to Paint Between Deck Boards)

What is CFM and its Relation to HVAC Systems?

CFM, or cubic feet per minute, is a measurement used to quantify the amount of air movement in an HVAC system. It is essential in HVAC systems because it determines how effectively air is circulated and distributed throughout a space.

Several factors can affect the CFM in an HVAC system, including the size of the space being cooled or heated, the desired temperature and humidity levels, and the insulation of the building. CFM can be measured using specialized tools such as airflow meters or calculated based on the system’s motor capacity and blower fan size. The general rule of thumb for CFM per ton in HVAC systems is 400, although this may vary depending on specific conditions such as humidity levels.

How is CFM defined in HVAC?

When it comes to HVAC systems, understanding the importance of airflow is crucial for contractors. This is to ensure a long-lasting and efficient system. CFM, or cubic feet per minute, measures airflow in HVAC systems. It refers to the amount of air that moves through the system per minute. CFM per ton is used to determine the appropriate airflow for optimal performance in the case of cooling capacity. Now let’s explore why CFM is vital in HVAC systems.

Why is CFM important in HVAC systems?

Ensure you understand why airflow measurements are crucial for optimal performance and efficiency in HVAC systems. CFM per ton is a key metric used to determine how much air an HVAC unit can deliver. It is essential to have the proper airflow for the air handler and air ducts to distribute cooled or heated air throughout the space properly. The general rule is 400 CFM per ton, which ensures efficient cooling and heating.

Now let’s explore what factors affect the CFM in an HVAC system.

What factors affect the CFM in an HVAC system?

Factors such as climate, home size, insulation, and humidity levels are all critical players in achieving the perfect airflow in an HVAC system.

- Climate: Humid climates require less air movement for AC units due to removing moisture, while dry climates require more CFM due to higher latent heat.

- Home Size: Larger homes may require more CFM to cool or heat the space effectively.

- Insulation: Well-insulated homes may only require a lower CFM per ton of cooling.

- Humidity Levels: High humidity levels may require lower CFM to increase dehumidification rates.

Now let’s explore how the CFM can be measured in an HVAC system.

How can the CFM be measured in an HVAC system?

Measuring the CFM in an HVAC system is crucial to ensuring optimal airflow and heating and cooling system performance. To calculate CFM, you can use tools such as an anemometer or a flow hood to determine the air velocity at various points within the system.

Additionally, you can calculate CFM per ton by dividing the total CFM by the cooling capacity of your unit. It’s also essential to consider CFM per square foot when designing your duct system to ensure proper air distribution. Finally, measuring return air is essential for determining if your system is operating efficiently. Transitioning into the next section, let’s explore the rule of thumb for CFM per ton in HVAC systems. (Learn How To Change Led Light Color Without Remote)

What is the rule of thumb for CFM per ton in HVAC systems?

Ensure optimal airflow and performance in your HVAC system by following the rule of thumb for CFM per ton, which helps determine the proper air movement for efficient cooling and heating. Here is a table that outlines the recommended CFM per ton for different HVAC systems:

| AC Unit Size | Recommended CFM |

|---|---|

| 1 ton | 400 |

| 2 tons | 800 |

| 3 tons | 1200 |

| 4 tons | 1600 |

| 5 tons | 2000 |

This rule of thumb provides a starting point for determining the appropriate airflow in your ductwork. It’s essential to consider factors like home size, climate, and insulation when choosing how many CFM is required per ton of cooling capacity.

How Many CFM is Required Per Ton of Cooling Capacity?

Regarding HVAC systems, the typical requirement is around 400 CFM (cubic feet per minute) per ton of cooling capacity. This means that a 5-ton unit would require approximately 2,000 CFM.

However, it’s important to note that the recommended CFM per ton ratio can vary based on humidity levels and climate conditions. While exceeding the recommended CFM per ton ratio may improve performance in some cases, inadequate CFM per ton can lead to problems such as poor air circulation, inefficient cooling or heating, and potential damage to the system.

How much is CFM typically required per ton of cooling?

The typical rule of thumb is that a residential cooling HVAC system should have 400 cfm per ton of air across its evaporator coil, meaning a 5-ton unit would require approximately 2,000 cfm for optimal performance. This calculation considers the cooling capacity and airflow needs of the HVAC equipment. Ensuring proper airflow per ton and square foot is essential to maintain efficient and comfortable cooling.

Now let’s discuss the recommended cfm per ton ratio in HVAC systems.

What is the recommended CFM per ton ratio in HVAC systems?

Maintaining the recommended airflow ratio to cooling capacity can achieve optimal performance and comfort in HVAC systems. The recommended CFM per ton ratio in HVAC systems is typically 350-400 CFM. This means that for a 5-ton unit, the recommended CFM would be around 1750-2000. It’s essential to ensure the system’s airflow matches its cooling capacity to prevent issues such as poor air circulation or uneven temperatures.

Let’s explore whether the CFM requirement differs for different HVAC units.

Does the CFM requirement differ for different HVAC units?

Different types of HVAC systems may have varying CFM requirements to ensure optimal performance and comfort. The CFM per ton ratio for a 5-ton unit can vary depending on the specific HVAC unit and its cooling capacity. To give you an idea, here is a table outlining the broad range of CFM requirements for different HVAC units:

| HVAC Unit Size | CFM per Ton |

|---|---|

| 1-2 tons | 350-400 |

| 3-4 tons | 375-425 |

| 5-6 tons | 400-450 |

| 7+ tons | 425-475 |

These values serve as a guideline, but it’s essential to consult the manufacturer’s specifications and industry standards to determine the precise CFM requirement for your specific HVAC unit. In the next section, let’s explore whether the CFM per ton ratio can be exceeded for improved performance.

Can the CFM per ton ratio be exceeded for improved performance?

Consider this: exceeding the recommended CFM per ton ratio for improved performance may seem tempting, but it could negatively affect your HVAC system. The CFM per ton ratio is based on the cooling capacity of your air conditioner and ensures proper airflow. Exceeding this ratio can strain the system, reducing efficiency, increasing wear and tear, and potential damage.

It’s essential to stick to the rule of thumb for optimal performance. Now let’s explore the consequences of inadequate CFM per ton in HVAC systems.

What are the consequences of inadequate CFM per ton in HVAC systems?

Exceeding the recommended CFM per ton ratio may seem tempting, but it can affect HVAC systems. Inadequate CFM per ton can lead to several issues. One consequence is reduced cooling capacity and inefficient air changes per hour. Insufficient airflow can also result in uneven cooling or heating throughout the space and increased energy consumption.

To ensure optimal performance, it’s crucial to maintain the proper CFM per ton ratio in both heating and cooling modes.

Now let’s explore how to calculate the necessary CFM for a 5-ton unit. (Learn How To Tell If Dehumidifier Is Working)

Calculating CFM for a 5-Ton Unit

To calculate the required CFM for a 5-ton unit, consider home size, climate, humidity levels, and insulation factors. These factors will determine the appropriate airflow needed for efficient cooling. The ductwork can also impact the CFM for a 5-ton unit, as undersized or improperly designed ducts can restrict airflow. It’s recommended to have an air velocity of around 600-900 feet per minute in the ducts of a 5-ton HVAC unit to ensure proper airflow and system performance.

Additionally, the type and capacity of HVAC equipment used in a 5-ton unit can affect the CFM requirements, so choosing equipment compatible with your specific needs is essential.

How to calculate the required CFM for a 5-ton unit?

Calculating the required CFM for a 5-ton unit involves considering home size, climate, humidity levels, and insulation factors. To determine the appropriate CFM for a 5-ton unit, you can use the industry standard rule of thumb of 400 CFM per ton of cooling capacity. A 5-ton team would require approximately 2000 CFM of airflow.

However, it’s important to note that this rule may not always apply, and other factors should be considered when calculating CFM for a specific HVAC unit.

What factors should be considered when calculating CFM for a specific HVAC unit?

When determining the necessary airflow for a specific HVAC system, it’s crucial to consider factors such as home size, climate conditions, insulation, and humidity levels. These factors can significantly influence the required CFM per ton of cooling. For example, lower CFM may be needed in hot and humid climates to effectively remove moisture from the air. On the other hand, in dry climates with higher latent heat, a higher CFM may be necessary for optimal cooling. It’s essential to consider these factors to ensure proper heating and cooling performance, maintain air speed across the evaporator coil, minimize static pressure drop, and promote good indoor air quality.

| Factors Considered | Recommended CFM per Ton |

|---|---|

| Home Size | Varies based on square footage |

| Climate Conditions | Higher humidity requires lower CFM |

| Insulation Levels | Well-insulated homes need less CFM |

| Humidity Levels | Varies based on relative humidity |

These factors must be considered when calculating the required CFM for a specific HVAC unit to determine the appropriate airflow. Can the ductwork impact the CFM for a 5-ton team?

Can the ductwork impact the CFM for a 5-ton unit?

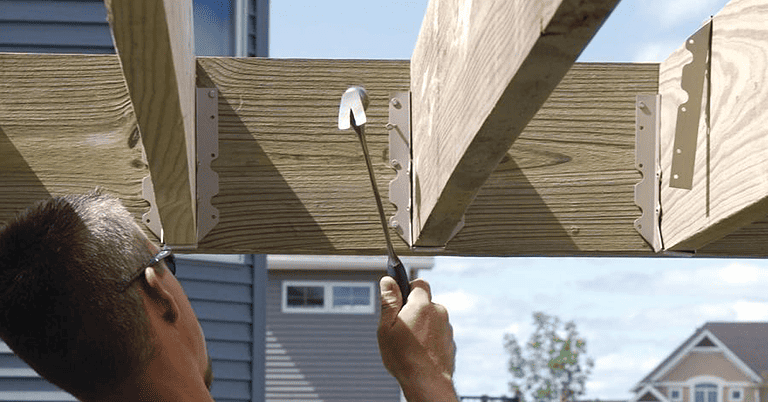

The ductwork significantly impacts the airflow for a 5-ton HVAC system. It’s crucial to consider the ductwork when determining how much CFM per ton of air cooling the air needs. Here are three ways that ductwork can affect airflow in a 5-ton system:

- Duct size: Properly sized ducts ensure that the required CFM per ton is delivered efficiently and evenly throughout the space.

- Duct design: The layout and design of the ductwork can impact airflow resistance, affecting the system’s overall performance.

- Duct leakage: Leaky ducts can lead to airflow loss, reducing the cooling process’s effectiveness and efficiency.

These factors will help determine how many CFM per ton your 5-ton system requires.

Now let’s explore what’s recommended for air velocity in ducts for a 5-ton HVAC unit.

What is the recommended air velocity for ducts in a 5-ton HVAC unit?

To optimize the performance of your 5-ton HVAC system, it is recommended that you ensure the air velocity in your ducts falls within the appropriate range. The air velocity in your ducts is measured in cubic feet per minute (CFM) and plays a crucial role in cooling the air efficiently. The recommended air velocity for vents in a 5-ton HVAC unit is typically around 800-900 feet per minute. This ensures enough air supply to maintain the desired temperature throughout your space. Moving on to how HVAC equipment affects the CFM for a 5-ton unit…

How does HVAC equipment affect the CFM for a 5-ton unit?

To ensure optimal system performance, the CFM for a 5-ton unit is influenced by HVAC equipment factors. The air coming from the blower fan affects the temperature of the air being distributed throughout the ducts. Proper sizing and equipment selection can optimize CFM levels for a 5-ton AC unit.

Now, let’s explore how to further optimize CFM for a 5-ton unit by considering duct design and airflow balancing techniques.

Optimizing CFM for a 5-Ton Unit

To optimize the CFM for a 5-ton HVAC unit, you can adjust the airflow to improve performance. Adjusting the CFM per ton ratio ensures that the unit operates efficiently and effectively. However, exceeding the recommended CFM per ton ratio can have potential drawbacks, such as increased energy consumption and decreased system longevity.

To modify HVAC ductwork for optimal CFM in a 5-ton unit, you may need to consider resizing or redesigning the ducts to accommodate the desired airflow.

How can the CFM be adjusted for improved performance in a 5-ton HVAC unit?

One way to improve performance in a 5-ton HVAC unit is by adjusting the CFM based on home size, climate, and insulation factors. To optimize the CFM for a 5-ton team, consider the following:

- Determine the recommended CFM per ton based on home size and temperature.

- Adjust the blower speed or fan settings to increase or decrease airflow.

- Ensure ductwork is properly sized and sealed to prevent air leakage.

- Use zoning techniques to customize airflow in different areas of the home.

Now let’s explore the benefits of optimizing CFM for a 5-ton unit.

What are the benefits of optimizing CFM for a 5-ton team?

Optimizing the CFM for a 5-ton HVAC unit can enhance energy efficiency, improve indoor air quality, and provide more precise temperature control throughout the home. The HVAC industry recommends 400 CFM per ton of cooling capacity. Ensuring that the airflow matches this recommendation allows you to effectively distribute cool air and remove sensible heat from your space.

Properly sized return ducts will also help remove latent heat and maintain a comfortable environment. However, exceeding the recommended CFM per ton ratio can have potential drawbacks.

What are the potential drawbacks of exceeding the recommended CFM per ton ratio?

Exceeding the recommended airflow ratio can lead to inadequate dehumidification, increased energy consumption, and potential system damage. When the CFM per ton exceeds the recommended balance, the cooling capacity may not effectively match the air movement. This can reduce moisture removal from the air, leading to higher humidity levels indoors. Additionally, excessive airflow can increase energy consumption and strain the HVAC system components unnecessarily. However, it’s essential to consider whether increasing the CFM for a 5-ton unit without compromising efficiency is possible.

Can we increase the CFM for a 5-ton unit without compromising efficiency?

Increasing the airflow for a 5-ton unit while maintaining efficiency can be challenging, requiring careful consideration of system design and components. When increasing CFM for a 5-ton team, it’s essential to ensure that the heat pump properly removes the moisture from the air. Higher airflow can lead to colder air and potentially cause discomfort. It’s crucial to balance these factors and find the right balance between many ACHs and less CFM per ton of cooling to avoid overworking the compressor.

Now, let’s explore how HVAC ductwork can be modified to optimize CFM for a 5-ton unit.

How can HVAC ductwork be modified to optimize CFM for a 5-ton unit?

Improve the performance of your HVAC system by making modifications to your ductwork, allowing for optimal airflow and better cooling for your 5-ton unit.

To optimize CFM for a 5-ton unit, consider the following:

- Increase duct size: Use larger ducts to accommodate higher airflow requirements.

- Reduce bends and turns: Minimize the number of angles and turns in your ductwork to reduce static pressure drop.

- Seal air leaks: Ensure all joints and connections are properly sealed to prevent leakage.

- Balance airflow: Use dampers or adjustable registers to balance airflow throughout the system.

These modifications will help optimize CFM for your 5-ton unit, ensuring efficient cooling performance.

The following section will discuss common issues with CFM in HVAC systems.

Common Issues with CFM in HVAC Systems

Inadequate CFM in HVAC systems can lead to a range of common problems. Insufficient airflow can result in poor heating or cooling performance, uneven temperature distribution, and reduced indoor air quality. Identifying the root causes, such as undersized ductwork, dirty filters, or duct leakage, is essential to resolve airflow issues and address them accordingly.

Excessive CFM in an HVAC system can also have consequences, including increased energy consumption, decreased dehumidification capabilities, and potential damage to the equipment. Duct leakage can significantly impact CFM by allowing air to escape before reaching its intended destination. Signs of improper CFM in an HVAC system may include hot and cold spots throughout the space, reduced comfort levels, excessive dust accumulation, and frequent system cycling.

What are the common problems associated with inadequate CFM in HVAC systems?

Low CFM in HVAC systems can lead to various issues, including hot and cold spots throughout the space, imbalanced pressure levels, and improper heating and cooling controls. This lack of airflow can also result in too much moisture in the air, causing discomfort and potential damage to the system. To ensure adequate CFM per ton, it’s essential to properly size ductwork and consider factors like home size and insulation.

In the next section, we’ll discuss how airflow issues can be resolved in an HVAC system.

How can airflow issues be resolved in an HVAC system?

Ensure optimal airflow in your HVAC system by addressing any issues hindering airflow. One standard solution is to adjust the fan speed or blower motor to increase or decrease the circulated CFM (cubic feet per minute) of air. Additionally, checking and cleaning air filters regularly can help improve airflow. If ductwork is undersized or leaking, it may need to be repaired or replaced. By resolving these airflow issues, you can improve the efficiency and performance of your HVAC system.

| Solution | Description |

|---|---|

| Adjust Fan Speed | Increase or decrease CFM by adjusting fan speed or blower motor settings. |

| Clean Air Filters | Regularly check and clean air filters to ensure proper airflow. |

| Repair/Replace Ductwork | Address undersized or leaking ductwork by repairing or replacing it. |

Next, let’s explore what consequences excessive CFM in an HVAC system can have on its performance and efficiency.

What are the consequences of excessive CFM in an HVAC system?

Excessive CFM in an HVAC system can wreak havoc on its performance and efficiency, leading to skyrocketing energy bills, decreased comfort levels, and potential equipment damage. When the CFM exceeds the recommended levels for a specific tonnage, it can cause the system to cool or heat too quickly, resulting in short cycling. This not only wastes energy but also puts unnecessary strain on the equipment.

Now let’s explore how duct leakage can affect the CFM in an HVAC system.

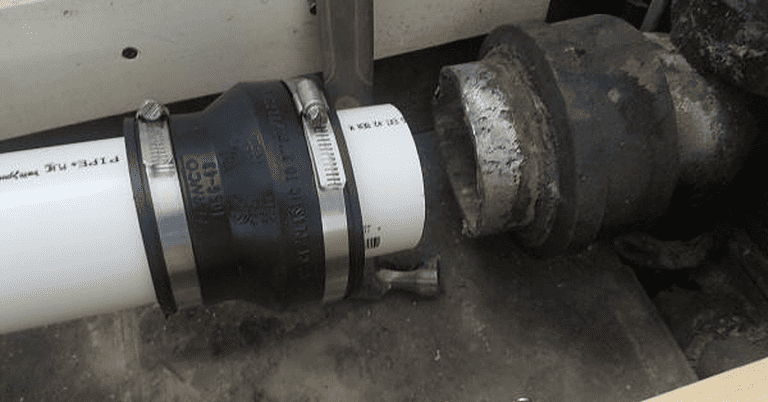

How can duct leakage affect the CFM in an HVAC system?

Is your HVAC system not performing at its best? Did you know that duct leakage could affect your system’s air movement? Here’s how duct leakage can impact CFM in an HVAC system:

Duct leaks can cause air to escape, reducing the overall airflow in the system.nn2. Leaks can create pressure imbalances, leading to uneven heating or cooling throughout your home.nn3. Decreased airflow due to leaks can strain the HVAC equipment, reducing efficiency and increasing energy consumption.nn4. Leaks can also introduce contaminants into the system, affecting indoor air quality.

Now let’s explore what signs to look for if you suspect improper CFM in your HVAC system.

What are the signs of improper CFM in an HVAC system?

There’s no denying it – when your HVAC system isn’t performing as expected, you might notice some telltale signs that the airflow isn’t correct. These signs include hot and cold spots throughout your home, pressure imbalances in different rooms, and improper heating and cooling controls. These issues indicate that your HVAC system’s CFM (cubic feet per minute) is incorrectly balanced, leading to inefficient and ineffective air distribution. Addressing these signs promptly ensures optimal performance and comfort in your space. (Learn Can You Lay Propane Tanks On Their Side)

Conclusion

Congratulations! You’ve now discovered the secret to determining the perfect CFM for a 5-ton unit in HVAC systems. By understanding the relationship between CFM and cooling capacity, you can ensure optimal airflow for efficient and effective cooling.

But wait, there’s more! Don’t forget to consider factors like humidity levels and insulation to fine-tune your CFM calculations. Remember, proper sizing of ductwork is crucial for achieving ideal airflow.

So, arm yourself with knowledge and let your HVAC system unleash its full potential!