How To Connect PVC To Cast Iron

Are you looking to connect PVC pipes to cast iron pipes? If so, you’ve come to the right place. This article will guide you through the step-by-step process of making a secure and functional connection between these two types of pipes. Before we dive into the details, let’s first understand the basics. PVC and cast iron pipes are commonly used in plumbing systems, and connecting them requires specific materials and techniques.

To begin with, you’ll need to gather all the necessary materials for this Project. This includes:

- PVC fittings

- Lengths of PVC pipe

- No-hub couplings with neoprene gaskets

- A reciprocating saw with a cast iron-rated blade

- A ratcheting torque wrench

Once you have everything ready, we will walk you through each stage of the connection process. From measuring and marking on the cast iron pipe to cutting it using a reciprocating saw, our detailed instructions will ensure accuracy and precision. Safety precautions are crucial during this procedure as well. We will emphasize the importance of using proper protective gear and following best practices to avoid accidents or injuries.

Lastly, we’ll cover common mistakes that can occur during this process and provide troubleshooting tips to help you overcome any challenges along the way. So get ready to tackle your PVC-to-cast-iron connection project confidently. Let’s jump right in! (Read Cost To Run Power 1000 Feet)

Understanding PVC and Cast Iron Pipes: An Introduction

If you’re looking to understand how to connect PVC pipes to cast iron, it’s essential first to grasp the basics of each type of pipe. PVC, or polyvinyl chloride, is a durable and cost-effective material commonly used in plumbing systems.

On the other hand, cast iron pipes have been used for centuries for their strength and durability. Understanding the differences between these two types of lines and their advantages and disadvantages will help you determine when it’s best to use PVC or cast iron for your plumbing needs.

What is a PVC Pipe?

PVC pipe is a versatile and commonly used material in plumbing systems. When it comes to connecting PVC to cast iron pipes, there are several methods available. One popular way is no-hub couplings, which provide a secure and leak-proof connection. These couplings allow you to easily connect PVC pipes to existing cast iron waste lines.

Now let’s move on to an overview of cast iron pipes and their characteristics.

Overview of Cast Iron Pipes

Cast iron pipes, known for their durability and longevity, have been a staple in plumbing systems for many years. One standard method for connecting PVC to cast iron is rubber couplings such as Fernco fittings. These flexible couplings allow for a secure connection between the two types of pipe.

Now let’s explore the differences between PVC and cast iron pipes.

Differences Between PVC and Cast Iron Pipes

Regarding plumbing materials, PVC and cast iron pipes are as different as night and day, like a gentle breeze on a summer’s eve versus the rumble of thunder in a storm. Here is a comparison between the two:

| Cast Iron Plumbing | PVC Pipe | Connect |

|---|---|---|

| Durable and long-lasting | Lightweight and easy to handle | Use no-hub couplings for connection |

| Resistant to rust and corrosion | Susceptible to UV damage if exposed outdoors | Can tie into existing cast iron lines |

| Quieter operation due to sound-dampening properties | It can be not quiet when water flows through it | No welding or soldering required |

These differences are essential in deciding which type of pipe best suits your plumbing needs. The following section will explore the advantages and disadvantages of PVC and cast iron pipes.

Advantages and Disadvantages of PVC and Cast Iron Pipes

Choosing a suitable plumbing material can significantly impact the durability and performance of your system. When it comes to connecting PVC to cast iron pipes, there are several options available. One popular method is using no-hub couplings, which allow you to tie new PVC pipe to an existing cast iron line. This eliminates the need for cutting cast iron pipe and provides a secure connection. However, it’s always best to consult a professional plumber before making decisions. (Learn How Long Do Pex Pipes Last)

So, when should you use PVC or cast iron pipes?

When to use PVC or Cast Iron Pipes?

For optimal performance and durability in your plumbing system, it’s essential to consider the specific needs of your project before deciding whether to use PVC or cast iron pipes. Using no-hub couplings makes it easy to tie new PVC lines with existing cast iron pipes. These couplings create a secure connection between the materials, allowing flexibility and movement. No-hub couplings provide a reliable solution for connecting vertical or horizontal lines.

Now, let’s prepare for the connection: gathering the necessary materials.

Preparing for the Connection: Gathering Necessary Materials

To prepare for connecting PVC to cast iron pipes, you’ll need several tools, including a reciprocating saw and a pipe cutter. Selecting the correct size PVC pipe for the connection is essential to prevent leakage. The Fernco coupling is a crucial component that allows for a secure and flexible connection between the two types of lines. Additionally, the practical use of a no-hub collar should be considered as it provides a reliable and efficient solution for joining PVC and cast iron pipes in drain, waste, and vent systems.

List of Tools Needed for Connecting PVC to Cast Iron

Before connecting PVC to cast iron, gather the necessary tools for the job. For example, grab a pipe cutter, a reciprocating saw, no-hub connectors, and a Phillips screwdriver or socket wrench.

- Pipe cutter

- Reciprocating saw

- No-hub connectors

- Phillips screwdriver or socket wrench

These tools will help ensure a proper fit and prevent leaks in your plumbing system. Once you have all the tools ready, select the suitable PVC pipe for your Project.

Selecting the suitable PVC pipe

When choosing the appropriate PVC pipe, it’s essential to consider factors such as diameter, schedule, and material composition. Selecting a suitable line for connecting PVC to cast iron pipes is crucial for a secure and leak-free connection. The chosen PVC pipe should have the same diameter as the cast iron pipe and be suitable for drain, waste, and vent lines.

Now let’s discuss the importance of using a reciprocating saw in this Project.

Importance of Using a Reciprocating Saw in this ProjectAa reciprocating saw is crucial for effortlessly cutting through the pipe and achieving a precise connection between PVC and cast iron. With these tools, you make clean, accurate cuts on both materials, ensuring a secure attachment. When connecting PVC to cast iron, it’s essential to have the right tools for the job. A reciprocating saw with a cast iron-rated metal-cutting blade is necessary for this Project. Now let’s move on to an overview of the fernco coupling and its role in this process.

Overview of the Fernco coupling

Now let’s discuss the Fernco coupling, a popular choice for connecting PVC to cast iron pipes. This rubber coupling is designed specifically for drain and vent lines and provides a tight seal between the materials. The Fernco coupling features a slip joint design, allowing easy installation without special tools. It’s commonly used in basements to connect PVC pipes to cast iron drain lines. (Learn How To Connect Two Hoses Together)

Now, let’s explore the practical uses of a no-hub coupling in this Project.

Practical Uses of a No-Hub Coupling

Discover the incredible versatility and time-saving convenience of a no-hub coupling for effortlessly joining different pipe materials in your plumbing project.

- No-hub couplings are practical solutions when connecting cast iron and PVC pipes. They provide a secure connection without the need for lead and oakum.

- No special tools or skills are required, making it an easy DIY project.

Now, let’s dive into the step-by-step guide on attaching PVC to a cast iron pipe.

The Step-by-step Guide on Attaching PVC to a Cast Iron Pipe

To connect PVC to a cast iron pipe, you’ll first need to cut the cast iron pipe using a reciprocating saw or a unique tool.

Next, position the new PVC pipe into the opening of the cast iron pipe and make sure it’s aligned properly.

Then, install and tighten a Fernco coupling over the connection to ensure a leak-free joint.

Finally, check for alignment and proper plumbing of the connected pipes before proceeding with further steps.

Cutting the Cast Iron Pipe

First, you must cut the cast iron pipe using a reciprocating saw or a unique cutting tool. Measure and mark the cut on the pipe’s diameter, then use a reciprocating saw with a cast iron-rated metal-cutting blade tocutt. After cutting, wipe the line clean of debris and remove any burrs with a file. This will prepare the line for installing the new PVC pipe.

Next, you can proceed to position the new PVC pipe.

Positioning the New PVC Pipe

Place the PVC pipe in the desired location, ensuring it aligns perfectly with your vision for a properly functioning plumbing system. Positioning the new PVC pipe is crucial for a successful connection between cast iron and PVC. The pipe should be straight and at the proper pitch.

Ensure that there are no obstructions or interference with other pipes or structures. Take measurements to ensure accuracy before proceeding.

Now that you’ve positioned the new PVC pipe, let’s install and tighten the coupling. (Learn How To Fix A Stripped Screw Hole Metal)

Installing and Tightening the Fernco Coupling

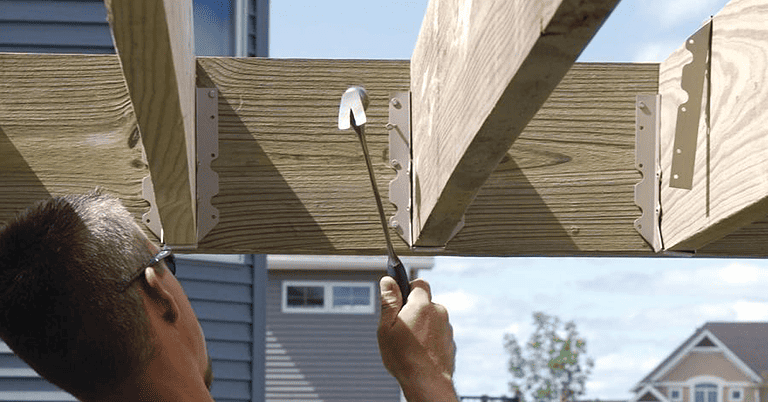

Now comes the pivotal moment to bring it together – securing the Fernco coupling and ensuring a watertight connection between these materials. To make it easy to tie in old cast iron drain or vent lines with new PVC, you’ll need to use a Fernco coupling. Slide the collar onto the end of the cast iron pipe and tighten down the stainless-steel bands using a ratcheting torque wrench.

With the Fernco coupling securely in place, you can move on to ensuring a leak-free connection.

Ensuring a Leak-free Connection

To achieve a watertight seal between different pipe materials, securing the Fernco coupling and preventing any potential leaks properly is crucial. Here are some essential tips to ensure a leak-free connection:

- Make sure to tighten the clamps evenly on all sides.

- Inspect the rubber gasket for any damage or wear.

- Check for proper alignment of the pipes before tightening.

- Use a torque wrench to achieve the recommended tightness.

- Apply PVC primer and cement to create a strong bond.

Now that you’ve secured the Fernco coupling, let’s move on to ensuring alignment and proper plumbing of the connected pipes.

Ensuring Alignment and Proper Plumbing of the Connected PipesEnsuree, you align the newly connected pipes properly, like a skilled plumber guaranteeing the perfect fit in a complex puzzle. It’s crucial to ensure proper alignment when connecting PVC to cast iron using a no-hub coupling. This ensures the sewer system functions efficiently and prevents leaks or blockages. Proper alignment also helps to maintain the correct pitch for waste flow, preventing any issues with toilets or other plumbing fixtures.

Now let’s discuss the role of safety precautions in this connection process.

The Role of Safety Precautions in the Connection Process

When connecting PVC to cast iron pipes, it’s essential to prioritize safety precautions. This includes wearing protective gear such as gloves and goggles to prevent injuries. Additionally, you should ensure the safe use of a reciprocating saw and handle both cast iron and PVC materials properly to avoid accidents.

It’s also crucial to take measures to prevent leaks and have a plan in place in case of accidental pipe damage during installation.

The Importance of Protective Gear

Ensure you prioritize your safety by wearing protective gloves and goggles when handling tools. Remember, accidents can happen, so it’s essential to take precautions.

Here are some reasons why protective gear is crucial:

- Prevents injuries from sharp objects and flying debris

- Reduces the risk of eye damage from sparks or particles

- Shields hands from cuts, abrasions, and chemical exposure

- Enhances grip for better control and stability

- It gives peace of mind knowing you’re protected

Now let’s move on to the safe use of a reciprocating saw.

Safe Use of a Reciprocating Saw

To keep all your digits intact, strap on those safety goggles and grip that reciprocating saw tight. Before cutting, ensure the blade is specifically designed for cutting cast iron. A Diablo Carbide-tipped metal-cutting blade is recommended for this job.

Always follow proper safety procedures when using power tools and be cautious of flying debris. Once your saw and blade are ready, let’s move on to adequately handling cast iron and PVC materials.

Proper Handling of Cast Iron and PVC Materials

Handle the sturdy cast iron and durable PVC materials carefully as you navigate this plumbing project, ensuring a successful connection that’ll bring peace of mind to your home. Remember to wear protective gloves and goggles when handling these materials. When working with cast iron, use a reciprocating saw or specialized cutting tool designed for this purpose. For PVC, correctly measure and cut the pipe using a ratchet cutter or other appropriate means. (Read Cheap Alternative To Plant Saucers)

Now that you’ve handled the materials correctly let’s move on to precautions to avoid leaks.

Precautions to Avoid Leaks

Caution! Neglecting proper precautions to prevent leaks during connection could result in a disastrous flood, turning your home into a soggy nightmare. To avoid this catastrophe, carefully align and secure the no-hub couplings with the neoprene gaskets unfolded over the cast iron pipes. Tighten the nuts using a ratcheting torque wrench to ensure a watertight seal.

With these measures in place, you can proceed confidently with the installation without worrying about accidental pipe damage.

Measures in Case of Accidental Pipe Damage during Installation

If you accidentally damage a pipe during the installation process, don’t worry. Here are some measures you can take to address the issue:

- Immediately turn off the water supply to prevent any further damage.

- Use rubber and silicone repair tape to block minor leaks temporarily.

If the damage is significant, contact a professional contractor for assistance.

- Inspect the surrounding area for any potential water damage or signs of leakage.

- Once the issue is resolved, proceed cautiously and double-check all connections before continuing.

Now let’s move on to common mistakes and troubleshooting when connecting PVC to cast iron.

Common Mistakes and Troubleshooting when Connecting PVC to Cast Iron

When connecting PVC to cast iron pipes, avoiding over-tightening the Fernco Coupling is essential, as this can lead to damage and leaks. Ensure a proper fit by carefully measuring and aligning the lines to prevent slips during installation. Existing pipe damage, such as cracks or corrosion, should be repaired or replaced before connecting. Special considerations should be taken for concrete and basement installations, as these environments may require additional sealing methods.

While eyeballing alignment may seem sufficient, ensuring actual pipe alignment for a secure and leak-free connection is crucial.

Over-tightening of the Fernco Coupling: What can go wrong?

Be careful not to over-tighten the Fernco coupling, as it could lead to potential issues and complications when connecting PVC to cast iron pipes.

- Over-tightening can cause the coupling to crack or deform. It may result in leaks, leading to water damage.

- Excessive force can damage the pipe or fitting.

- The rubber gasket may become compressed, affecting its effectiveness.

- Over-tightening can make future repairs or replacements difficult.

Now let’s move on to ensuring proper fit: avoiding slips during installation.

Ensuring Proper Fit: Avoiding Slips during Installation

To ensure a proper fit and avoid slips during installation, it’s essential to follow a few key steps.

First, ensure the PVC pipe is clean and free of debris or burrs.

Next, slide the neoprene gasket onto the end of the PVC pipe and fold it back on itself.

Align the fitting assembly with the cast iron pipe and unfold the gasket.

Slip the bands over the gaskets and tighten them using a ratcheting torque wrench.

Now, let’s move on to dealing with existing pipe damage…

Dealing with Existing Pipe Damage

If you encounter any surprises with the existing pipes, such as minor mishaps or imperfections, there are clever ways to address them during installation. One option is using rubber and silicone repair tape to block minor leaks. This tape can be wrapped around the damaged area, providing a temporary fix until a more permanent solution can be implemented. Additionally, any burrs or debris on the cut edges of the pipe should be wiped away with a rag and removed using a file for smoothness.

| Unexpected Surprises | Solutions |

|---|---|

| Minor Leaks | Rubber and silicone repair tape |

| Burrs and Debris | Wipe away with a rag and remove using a file |

Now let’s discuss special considerations for concrete and basement installations.

Concrete and Basement Installations: Special Considerations

When working with concrete and installing pipes in a basement, you’ll want to consider some essential factors for a successful project.

- Ensure that the drain lines are straight, secure, and appropriately pitched.

- Use hangers or straps to hang the pipes at the correct height securely.

- Make sure to follow local building codes for basement plumbing installations.

Now that you have a solid understanding of installing pipes in concrete and basements, let’s discuss the importance of accurately aligning your lines.

Eyeballing Alignment vs. Actual Pipe Alignment

Imagine you’re in the midst of a plumbing project and are faced with eyeballing alignment or ensuring actual pipe alignment. It’s like choosing between a wild dance on the unsteady ground or a graceful waltz guided by precision. When connecting PVC to cast iron pipes, it is crucial to prioritize actual pipe alignment rather than relying on guesswork. This ensures a secure and leak-free connection that will stand the test of time.